Many batch processes require short-duration, high-flow rate steam daily or weekly. A steam accumulator accommodates these peaks by storing excess steam.

Steam accumulator main purposes could be defined:

Every steam system is different, although each time installation must be analyzed on a case-by-case basis.

Generally steam accumulator installations improve plant performance, reduced fuel costs and minimized greenhouse gas emissions. This effective and easy way to meet targets reduce carbon footprint in state or private company policies.

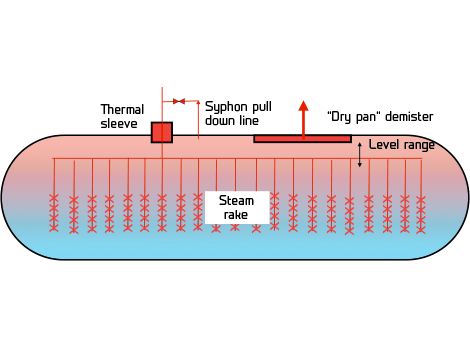

The 1st Sliding pressure steam accumulator was patented by McMahon in 1873. Steam accumulators were reinvented 100 years later in Scandinavian pulp&paper industry. “Steam Age” application is still valid modern industry; boilers holdup volumes are getting smaller, oil price keeps rising, biomass boiler have long response and emission reduction are topic. The 3rd Generation steam accumulator was introduced 1996 in Kirkniemi, Finland. New design features are: